High Strength PP Woven Geotextile for Road

Overview

Quick Details

| Warranty | NONE |

| After-sale Service | Online technical support, Onsite Installation |

| Project Solution Capability | graphic design, 3D model design |

| Application | Outdoor, Roads, railways, afforestation projects, etc. |

| Design Style | None |

| Place of Origin | Shandong, China |

| Model Number | woven geotextile |

| Geotextile Type | Woven Geotextiles |

| Type | Geotextiles |

| Color | White Black |

| Product name | Woven PP Geotextiles Fabric |

| Material | Short Polyester Fiber |

| Keyword | PP Woven Geotextile |

| Length | 50-100m/roll (at Request) |

| Width | 1-6m |

| Name | PP Woven Film Geotextile |

| Usage | Ecological Slope Protection System,etc |

Supply Ability : 600000 Square Meter/Square Meters per Month

Packaging & Delivery

Packaging Details : pack and ship according to your request

Port : Qingdao

Product Detail

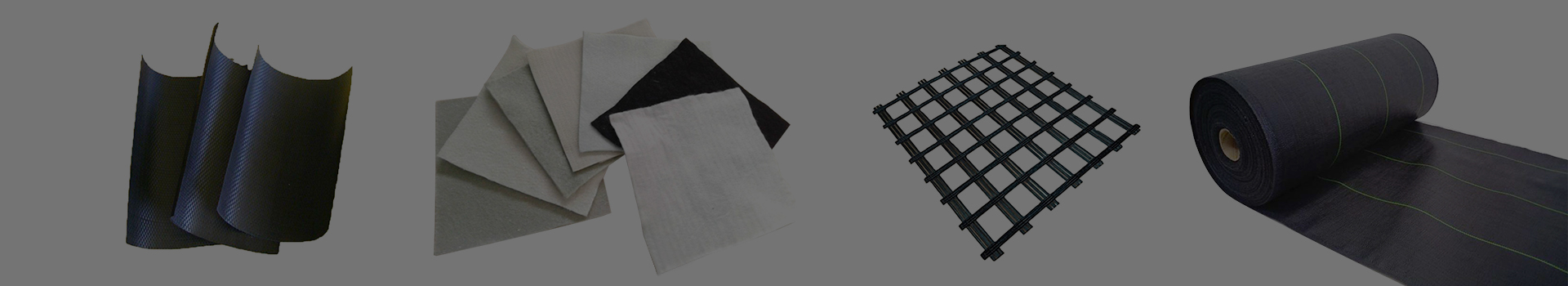

High strength PP woven geotextile for road construction

PP Woven Geotextile is made of virgin polypropylene fibers. polypropylene woven geotextile is woven and blended by parallel yarns (or tape yarn) with different weaving machines and technologies to weave the warps and wefts into textile-shape with various thickness and compactness according to different applications. pp woven geotextile is highly in strength. woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability. It is widely used in roads, pavements, railroads, structures and water conservancy project.

High water permeability

The warp-knit composite geotextile has high tensile strength, low elongation, uniform vertical and horizontal deformation, high

tear strength, excellent wear resistance, high water permeability, and strong infiltration resistance.

High tensile strength;

UV Resistant;

low elongation

PP woven geotextile feature is that the intersections of warp and weft are not bent, and each is in a straight state. Bundle the two firmly, can be more uniform and synchronous, withstand external forces, distribution of stress.

Specification

|

Model Project |

M-40 | M-60 | M-80 | U-40 | U-60 | U-80 | |

|

Tensile strength (KN / m) |

Vertical | 40 | 60 | 80 | 40 | 60 | 80 |

| Horizontal | 40 | 50 | 70 | 40 | 50 | 70 | |

|

Elongation(%) |

Vertical | 20 | 4 | ||||

| Horizontal | 20 | 4 | |||||

| Tear strength (KN / m) | 1.75 | 1.85 | 1.95 | 1.75 | 1.85 | 1.95 | |

| Compound type |

Warp knitting compound |

||||||

| Permeability coefficient |

K×(10-1——10-3);K=1.0-9.9 |

||||||

| Equivalent pore size |

0.07-0.2 |

||||||

| Remarks | M---High strength polyester warp knitted composite geotextile | U---Glass fiber warp knitted composite geotextile | |||||

Product application

PP Geotextile

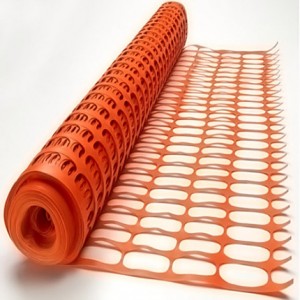

For highways, railways, airports, and other road enhancements;

PP Geotextile

For the maintenance of the old road ; For the subgrade strengtheing.

PP Geotextile

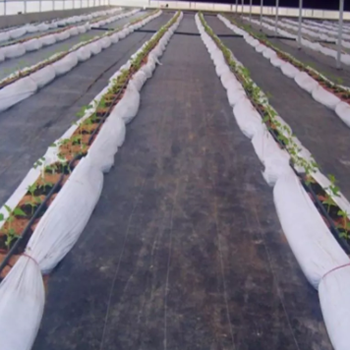

Road Project like soft foundation treatment, slope protection, road surface antireflection structure layer, drainage system, greenbelt.

PP Geotextile

Water conservancy project such as river bank, dam protection, diversion irrigation; reservoir seepage and consolidation project, Filling sandbags.