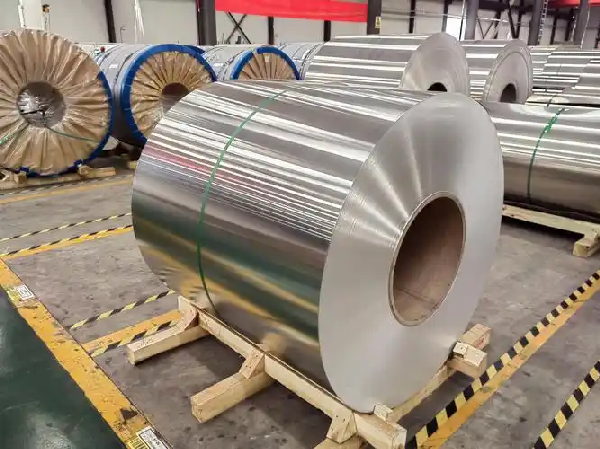

During the use of aluminum coils, due to some external factors, corrosion problems may occur, which may affect their service life. We need to do some protection work to avoid corrosion problems. Next, Mount Taishan nonferrous metal manufacturers will talk about what corrosion aluminum coils are afraid of and how to effectively avoid corrosion of aluminum coils.

Firstly, let’s talk about the reasons for oxidation and corrosion of aluminum coils: Under normal circumstances, oxidation refers to the complete contact between the surface of the aluminum coil and air after use, such as wrapping it on a pipeline, forming an oxide film. This oxide film will protect the aluminum coil from further corrosion. Therefore, even if it is exposed to rain or sunlight outdoors after use, the aluminum coil will not corrode. Corrosive oxidation refers to the situation where the surface of an aluminum coil is not fully exposed to air and has not formed a protective layer before use due to its packaged state. In this case, if the aluminum coil is exposed to water, rain, or moisture, the moisture in the moisture will react chemically with the surface of the aluminum coil, causing corrosion. The corroded aluminum coil will show corrosion marks, and in severe cases, it will turn black and black, as if it has been burned. But after this corrosion occurs, there will be no further secondary damage to the aluminum coil. The aluminum coil itself is not a problem, only the appearance is damaged.

Below are several reasons that can easily cause corrosion of aluminum coils and methods to avoid oxidation corrosion of aluminum coils. Please pay attention to them

(1) Aluminum coils should not be placed in areas with leaking rain or snow on the roofs of workshops and warehouses

(2) Strengthen the management of air dryness to ensure that there is no water in compressed air

(3) The packaging of aluminum foil rolls should be sealed, and an appropriate amount of desiccant should be placed in each roll

(4) Do not immediately open the sealed packaging when transporting from low-temperature areas to areas with high temperature and humidity

(5) Strengthen the management of rolling oil and control its moisture content below 0.04%

(6) The humidity of the wooden axis and box board of the packaging box shall not exceed 18%, and the temperature of the colored aluminum coil for packaging shall not exceed 45 ℃

Post time: Dec-09-2024