For better waterproofing, after the installation of the color coated board is completed, use a special tool to fold the color coated board by 3CM against the ridge, about 800.

The color coated panels transported to the roof truss were not fully installed on the same working day, so they were firmly fixed to the steel roof truss using scaffolding. The specific implementation can be to use brown ropes or 8 # lead wires to tie them firmly, which will avoid any damage to the color coated panels in strong wind weather.

The roof cover should be constructed as soon as possible after the completion of the roof slab. If it cannot be constructed immediately, plastic cloth should be used to protect the insulation material at the roof ridge to prevent the insulation effect from being affected by rainy days.

During the construction of the ridge cover plate, it should be ensured that the sealing between it and the roof, as well as between the ridge cover plates, is reliable.

When lifting the roof onto the roof truss for installation, pay attention to facing the mother rib of the color coated board towards the first installation direction. If it is not a mother rib, adjust it immediately. Make sure to check the verticality of the first board to the ridge and roof gutter to ensure that all dimensions are accurate

After the mistake, fix the first base plate and install the subsequent base plates using the same method, always using positioning to ensure that the ends of the color coated plate are neat and in a straight line.

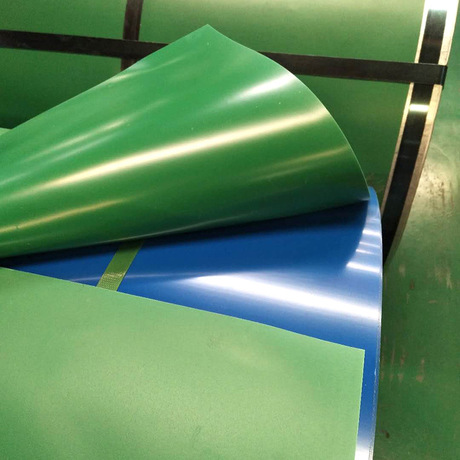

Installation of color coated board

(1) Vertically transport the board, ensuring that the mother rib is facing towards the beginning of installation. Install the first row of fixed brackets and fix them to the roof purlins, adjust their position, ensure the accuracy of the first top plate position, and fix the first row of fixed brackets.

(2) Arrange the first color coated board on the fixed bracket in the direction orthogonal to the gutter. Align the middle rib with the bending angle of the fixed bracket, and use foot ribs or wooden purlins to fasten the middle rib and mother rib onto the fixed bracket, and check if they are fully fastened.

(3) Secure the second row of fixed brackets onto the already installed color coated plate ribs and install them onto each bracket component.

(4) Fix the mother ribs of the second color coated board to the second row of fixed brackets, and tighten them from the middle to both ends. Install the color coated board in the same way, paying attention to the reliable connection and checking the accuracy of the verticality and position of the roof at the gutter at any time.

(5) During the installation process, always use positioning lines at the end of the board to ensure the parallelism of the color coated board itself and its perpendicularity to the gutter.

During the installation process, special attention should be paid to the following points:

(1) The top of the purlin used for support must be on the same plane, and its position can be adjusted by tapping or relaxing according to the actual situation to meet this requirement. It is strictly forbidden to directly hit the lower part of the fixed bracket in an attempt to adjust the slope or position of the roof. Correctly placing the painted board can ensure its effective fastening. On the contrary, if the painted board is not properly aligned, it will affect the fastening effect of the painted board, especially near the center point of the support.

(2) In order to avoid the formation of fan-shaped or scattered painted boards or uneven lower edges of the roof due to improper construction, the painted boards should be checked for proper alignment and the distance from the edges of the upper and lower ends of the painted boards to the gutter should be measured at all times to avoid tilting.

(3) Immediately clean up any remaining water droplets, rivet rods, discarded fasteners, and other metal debris on the roof after installation, as these metal debris can cause corrosion of the painted panels.

Construction of accessories such as corners and flashing

2. Laying of insulation cotton:

Before laying, the thickness of the insulation cotton should be checked for uniformity, and the quality assurance certificate and certificate of conformity should be checked for compliance with the design requirements.

When laying insulation cotton, it is required to be laid tightly, with no gaps between insulation cotton and fixed in a timely manner.

3. Laying of roof slab:

When laying the inner and outer panels of the roof, the overlapping of each edge shall be strictly carried out in accordance with the specifications. When installing the eaves, the installation position shall be determined by combining the bottom plate and glass wool. The installation shall start from the eaves and be laid in sequence from bottom to top. Section inspection shall be carried out to check the flatness of both ends and the flatness of the panels to ensure installation

Quality.

4. SAR-PVC waterproof roll sheets can be used for soft waterproofing in areas such as roof ridges and gutters, which can effectively solve the problems of joint and water leakage that cannot be solved by color plate structure waterproofing. The fixing point of PVC roll material is ensured to be fixed on the peak surface of the profiled board, ensuring that the fixing parts are subjected to reasonable force and the waterproof structure is reasonable.

5. Installation control of profiled steel plate:

① The installation of profiled metal plates should be flat and straight, and there should be no construction residue or dirt on the surface of the plate. The eaves and the lower end of the wall should be in a straight line, and there should be no untreated drilled holes.

② Inspection quantity: 10% of the area should be randomly inspected, and it should not be less than 10 square meters.

③ Inspection method: Observation and inspection

④ Deviation in installation of profiled metal plates:

⑤ The allowable deviation for the installation of profiled metal plates shall comply with the provisions in the table below.

⑥ Inspection quantity: Parallelism between eaves and ridges: 10% of the length should be randomly checked, and it should not be less than 10m. Other projects: One spot check should be conducted every 20 meters of length, and there should be no less than two spots.

⑦ Inspection method: Check with wire, suspension wire, and steel ruler.

Allowable deviation for installation of profiled metal plates (mm)

Project allowable deviation

Post time: Nov-05-2024