1. Construction site: It is required to be compacted, flat, horizontal, and remove sharp protrusions.

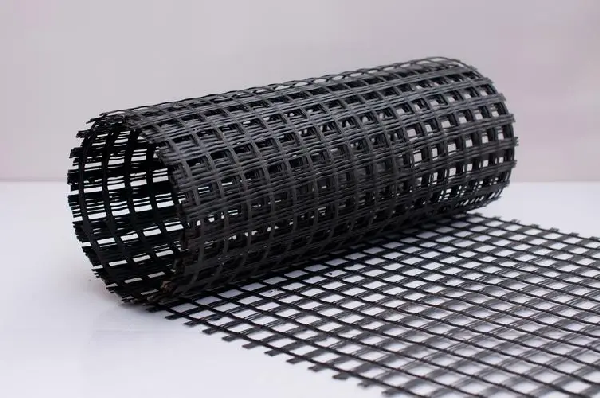

2. Grid laying: On a flat and compacted site, the main force direction (longitudinal) of the installed grid should be perpendicular to the axis of the embankment, and the laying should be flat, without wrinkles, and as tight as possible. Fixed by inserting nails and earth and stone weights, the main direction of force on the laid grid should be the full length without joints. The connection between the amplitudes can be manually tied and overlapped, with a width of no less than. If the grid is set up in more than two layers, the gaps between layers should be staggered. After laying a large area, the overall flatness should be adjusted. After filling a layer of soil and before rolling, the grid should be tensioned again using manual or machine tools, with even force, so that the Geogrid is in a straight and stressed state in the soil.

3. Selection of fillers: Fillers should be selected according to design requirements. Practice has proven that except for frozen soil, swamp soil, household waste, chalk soil, and diatomaceous earth, they can all be used as fillers. However, gravel soil and sand soil have stable mechanical properties and are less affected by water content, so they should be selected first. The particle size of the filler shall not be greater than, and attention shall be paid to controlling the grading of the filler to ensure the compaction weight.

4. Spreading and compaction of filling materials: After the Geogrid is laid and positioned, it should be covered with soil in a timely manner. The exposure time should not exceed 48 hours, and a flow process method of backfilling while laying can also be adopted. First spread the filler at both ends, fix the grille, and then push it towards the middle. The sequence of rolling is from both sides first to the middle. During rolling, the roller should not directly come into contact with the reinforcement material, and vehicles are generally not allowed to drive on the uncompacted reinforcement body to avoid misalignment of the reinforcement material. The compaction degree of each layer is 20-. The compactness must meet the design requirements, which is also the key to the success or failure of reinforced soil engineering.

5. Waterproof and drainage measures: In reinforced soil engineering, it is necessary to ensure proper drainage treatment inside and outside the wall; To protect feet and prevent erosion; Filter and drainage measures should be set up in the soil, and if necessary, geotextile and glass fiber geogrid should be installed. They are excellent geosynthetic materials used for road reinforcement, old road reinforcement, roadbed reinforcement, and soft soil foundation. In the application of treating reflective cracks on asphalt pavement, it has become an irreplaceable material.

Post time: Aug-25-2023