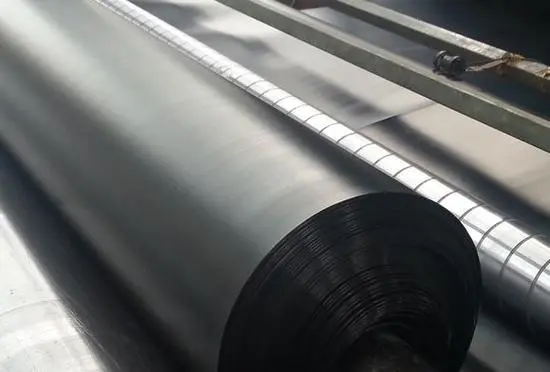

Cutting and transportation: Based on the measurement records of the laying surface, record the number of the large bundle of geomembrane cut and transport it to the laying site according to the number. Attention, do not drag or forcefully pull the geomembrane during transportation to avoid sharp objects from puncturing it.

Construction and installation of geomembrane laying:

1) It should extend from the bottom to the high position, without pulling too tightly, leaving a margin of 1.50% for local sinking and stretching. Considering the actual situation of this project, the slope will be laid in a top-down sequence.

2) The longitudinal joints of adjacent frames should not be on the same horizontal line and should be staggered by more than 1M from each other.

3) The longitudinal joint should be at least 1.50m away from the dam foot and bend foot, and should be set on a flat surface.

4) Start with the back bottom of the slope first.

5) When laying the slope, the direction of the film should be basically parallel to the slope line.

Slope laying: Before laying the anti-seepage geomembrane on the slope, the laying area should be inspected and measured. Based on the measured size, the anti-seepage membrane that matches the size in the warehouse should be transported to the first phase anchoring ditch platform. During laying, a convenient method of “pushing and laying” from top to bottom should be adopted according to the actual conditions on site. In the fan-shaped area, it should be cut reasonably to ensure that both the upper and lower ends are firmly anchored.

Bottom laying: Before laying the anti-seepage geomembrane, the laying area should be inspected and measured. Based on the measured size, the anti-seepage membrane that matches the size in the warehouse should be transported to the corresponding position. When laying, it is manually pushed in a certain direction. Alignment and alignment: The laying of HDPE geomembrane, whether on slopes or at the bottom of the site, should be smooth and straight, avoiding wrinkles and ripples, in order to align and align the two geomembranes. The overlap width is generally 10cm on both sides according to the design requirements.

Film pressing: Use sandbags to timely press the aligned and aligned HDPE geomembrane to prevent wind and pulling.

Laying in the anchoring ditch: A certain amount of anti-seepage membrane should be reserved at the top of the anchoring ditch according to the design requirements to prepare for local sinking and stretching.

Longitudinal joint: The uphill section is on top, the downhill section is on the bottom, and there is enough overlap length=15cm. After the acceptance of the bentonite pad laying, the area is laid manually in a certain direction.

Post time: Sep-10-2024