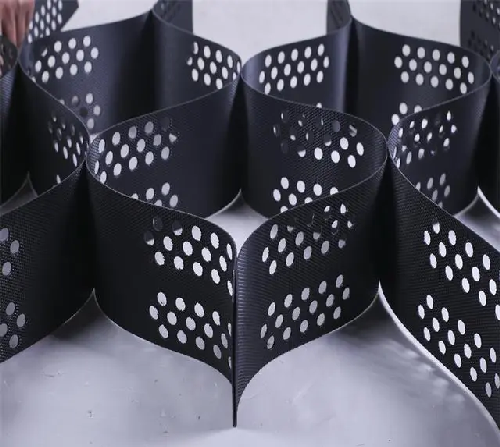

With the development of highways in the world, many problems have been exposed during use, such as road surface damage and roadbed settlement. These problems will affect the safety and comfort of driving, and will also affect the service life of the vehicle. Taishaninc geogrid shed is a new type of geosynthetic material. Compared with other materials, it has its unique performance and efficacy. It has high strength, strong load-bearing capacity, strong durability, easy construction and long service life. By using polyester geogrid reinforcement to improve the bearing capacity of the soft soil subgrade and reduce its post-construction settlement, the construction technology of polyester geogrid reinforced subgrade was systematically discussed, and feasible construction control technical measures were summarized. The implementation results of this project show that polyester geogrid has the advantages of high strength, strong load-bearing capacity, strong durability, convenient construction, and long service life, and can be used in similar projects.

Taishaninc polyester geogrid reinforced subgrade pavement is widely used in European highway construction. The main functions of polyester geogrid used in highways include reinforcement, protection, filtration, drainage and isolation. Polyester geogrid is mainly suitable for highway soft soil subgrade treatment, subgrade reinforcement, platform backfilling, splicing of new and old roads, filtration and drainage, etc.

Taishaninc polyester geogrid reinforced subgrade pavement is widely used in European highway construction. The main functions of polyester geogrid used in highways include reinforcement, protection, filtration, drainage and isolation. Polyester geogrid is mainly suitable for highway soft soil subgrade treatment, subgrade reinforcement, platform backfilling, splicing of new and old roads, filtration and drainage, etc.

(1) Before formal construction, polyester geogrid materials need to be selected according to design requirements. The polyester geogrid used in this project is unidirectionally stretched high-density polyethylene polyester geogrid. Before laying, the polyester geogrid should be inspected. If wrinkles are found, they should be straightened mechanically or manually.

2) The filler used in the project should meet the following requirements: the water permeability of the filler should be good, and its internal friction angle should be controlled within 30°. If necessary, on-site geotechnical tests should be conducted on the filler; there are sharp edges and corners in the filler. The soil content should be controlled within 15% of the total amount of material to avoid damage to the polyester geogrid caused by sharp edges; the particle size of soil particles in the filler should be controlled within 100mm.

When excavation and construction of the foundation bed, you only need to follow the general construction technology of the foundation bed. No further description in this article. However, during foundation bed excavation construction, special attention needs to be paid to ensuring that the foundation bed excavation meets the design. and construction requirements. At the same time, waterproofing and drainage measures should be taken in the foundation pit to reduce the adverse effects of water. When the excavation of the foundation bed is leveled and compacted, the gravel cushion can be laid after testing to ensure it is qualified. Its thickness should be controlled at 30cm. After the gravel cushion is laid, it should be leveled in time, and the local allowable height difference on the surface of the cushion should be controlled within 10cm. After the gravel cushion is laid, the laying of polyester geogrid can begin. First, cut the ground reinforced grating according to the design requirements, and then lay it out according to the requirements of the design drawings. A certain length of grating should be reserved outside the slope surface for back-packing. During the laying process of polyester geogrid, special attention should be paid to the fact that the stress direction of polyester geogrid should be laid along the longitudinal axis. Polyester geogrids should not have joints along the main stress direction.

When laying polyester geogrid, the location, length and direction set in the design drawings should be followed. The overlap width along the route should be controlled at 10cm. After the laying is completed, U-shaped nails are used to support the polyester geogrid. The spacing of the U-shaped nails should be maintained at an appropriate distance. The fixation of U-shaped nails can prevent the polyester geogrid from shifting during filling construction. The polyester geogrid’s joints along non-main stress directions are tied with nylon ropes, without the need for overlapping. The spacing between bindings should be controlled within lm.

After the polyester geogrid is laid as required, backfill construction should be carried out in time. The exposure time of polyester geogrid should not be too long to prevent aging problems caused by sun exposure. During the backfilling construction, the particle size of the filler used should not exceed 1/2 of the rolling layer. During the filling construction, the two ends of the polyester geogrid should first be filled and a longitudinal platform or traffic lane should be formed. , and then the scope of backfilling should be expanded in turn. During the rebound construction process of the filler, vehicle traffic is prohibited on the completed polyester geogrid.

Backfill leveling can be done mechanically or manually. After leveling treatment, the local height difference on the surface should be controlled within Scm. When rolling construction is carried out, it should be carried out in order from both ends to the middle. Reverse sequential construction methods are not allowed. During construction, the road roller should drive along the longitudinal direction of the embankment to avoid the phenomenon of horizontal driving and rolling. After the rolling construction of each layer of filler is completed, its compaction should be checked to ensure that it meets the requirements before proceeding with the construction of the next layer of filler. The compaction degree of the fill is controlled in accordance with the general requirements for embankments.

Taishan Industrial Development Group produces: geomembrane, geomembrane price, HDPE geomembrane, 1.0mm geomembrane price, 1.5mm geomembrane manufacturer, artificial lake geomembrane, slag yard geomembrane, ash dam geomembrane, tailings dam geomembrane, Oxidation pond geomembrane, biogas pool anti-seepage membrane, landfill HDPE geomembrane, garbage dump covering HDPE membrane, black and green two-color geomembrane, garbage dump geomembrane, hdpe geomembrane, artificial lake geomembrane, slag yard geomembrane, Ash dam geomembrane, tailings dam geomembrane, sewage pond anti-seepage membrane, lotus root pond anti-seepage membrane and other geotechnical materials.

Post time: Oct-16-2023