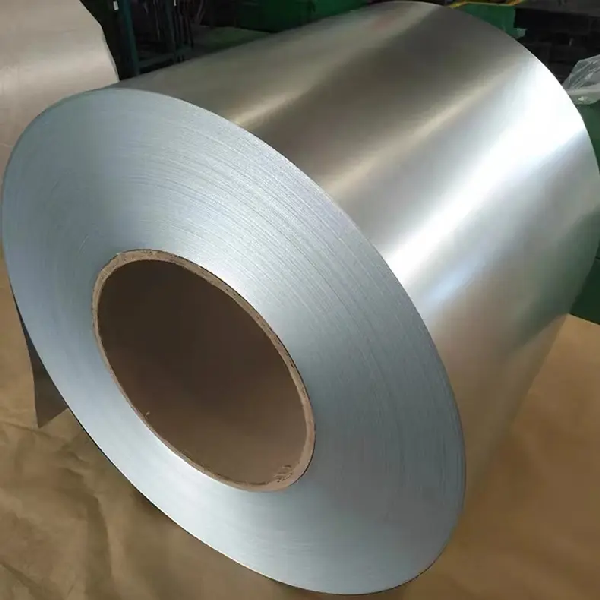

Galvanized sheet refers to a steel plate with a layer of zinc on its surface. Galvanization is an economical and effective method of rust prevention, which can achieve good rust prevention effects without consuming too much zinc. Most zinc is obtained through

The quality of galvanized sheet should be compared from various aspects such as stability and uniformity of galvanizing, and what are the advantages of galvanized sheet?

1、 Strong corrosion resistance

The treatment method of galvanizing is to achieve the effect of rust prevention. Therefore, galvanized sheet must have good corrosion resistance. The surface of galvanized sheet can withstand the erosion of corrosive products such as acid and alkali, and has

A certain level of impact resistance prevents surface coating damage. Galvanized sheets used in household appliances such as refrigerators and washing machines will be wiped multiple times to maintain cleanliness, so they also need to have a certain degree of waterproofing

Sex to prevent electric shock accidents.

2、 Diverse surface treatment methods

There are various methods of surface treatment, which can be roughly divided into hot-dip galvanizing, alloying galvanizing, and electrogalvanizing. Hot dip galvanizing is the process of immersing a thin steel plate into a dissolved zinc bath, during which a layer of zinc adheres to the surface

And to achieve rust prevention effect, this method can continuously galvanize and is therefore used for rolled steel plates. The length of the rolled steel plate is long, and continuous immersion galvanizing can achieve both dyeing and forming.

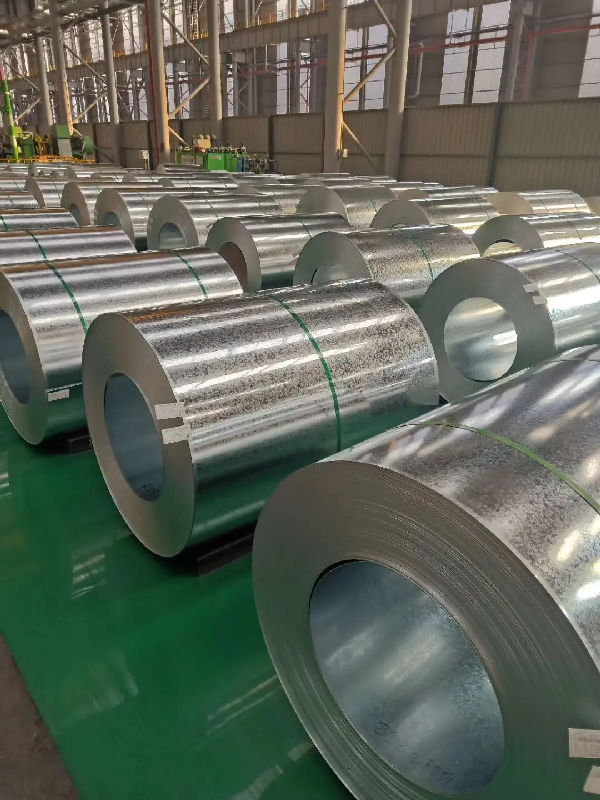

3、 Diverse product specifications

A good galvanized sheet has a variety of materials and product sizes. Generally, the product model is printed on the packaging or steel bottom of the product, which makes it more organized and improves the efficiency of transportation during classification and storage. plating

The size standard of zinc sheet allows for deviation, and the larger the thickness of galvanized sheet, the greater the allowable error. However, standardized production is used to strictly control the error of galvanized sheet.

The galvanized sheet undergoes special processing technology, which enables the coating to effectively protect the steel, prevent rust, and extend the service life of the steel. The hot-dip galvanized coating is thicker and more resistant to corrosion than the electroplating method

Stronger corrosiveness. For materials that require frequent contact with water and corrosive substances, it is recommended to use hot-dip galvanizing. Renowned galvanized sheets can control production errors and enable customers to purchase products of appropriate size.

Post time: Jul-05-2024