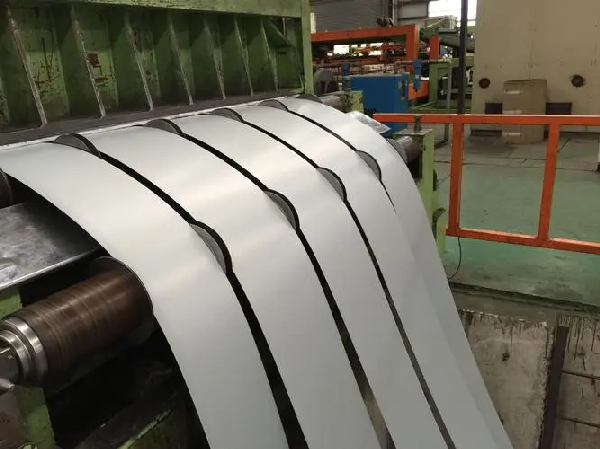

Brushing various materials on the surface of steel can provide surface protection and change its characteristics. Steel has high hardness and a wide range of applications, but it is prone to rusting. Materials such as zinc and tin have low activity and do not react with oxygen and water, making them less prone to rusting. What are the application areas of galvanized steel after processing?

1、 Tool raw materials

Galvanized sheet takes on the shape of a sheet after production, and can be directly processed into tools through cutting and shaping. For example, nuts, pliers, clamps, etc. can be directly cut and formed on the sheet, reducing the processing time. When the project schedule is tight, it saves a lot of time compared to starting with raw materials, and the remaining materials can also be remelted without waste.

2、 Building frame structural components

The material of galvanized sheet, which is highly favored by customers, has high hardness and strong toughness, and can withstand large weights. The load-bearing characteristics of galvanized sheet make it suitable as a structural component for building frames. When installing the load-bearing components of building frames, professional galvanized sheet can be used as a load-bearing component to improve the overall load-bearing capacity of the house and enhance its safety performance. Galvanized sheet can also be used to make handrails and other building materials, playing an important role in building materials.

3、 Home appliance hardware

The thickness of galvanized sheet varies according to different uses. The material thickness of building frame parts is generally large, so as to have a better bearing effect. The housing of household appliances is also made of galvanized sheet materials. This material is small in thickness but needs to have good corrosion resistance and aging resistance. The galvanized sheet used in household appliances needs to be coated with an additional layer of anti-corrosion material on the surface.

The diverse types and shapes of galvanized sheet can be applied to more production fields, and the material and functional characteristics of different production fields may vary. Therefore, when choosing, it is necessary to understand in advance to ensure the performance of galvanized sheet materials. It is recommended not to use sheet materials with damaged surfaces. It is important to ensure the integrity of the galvanized surface without any damage, as it can accelerate the rate of material damage.

Post time: Oct-09-2024