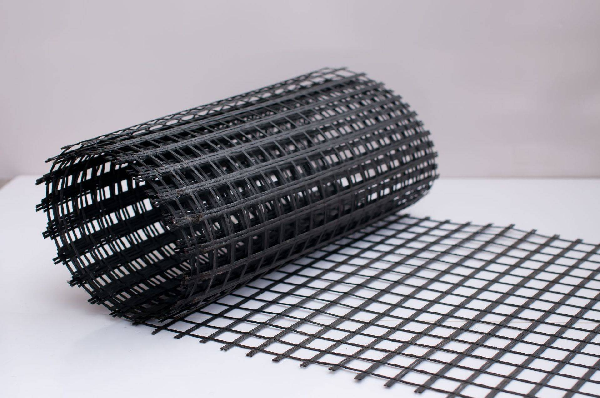

Plastic geogrid is a polymer mesh material with square or rectangular shape formed by stretching. It is punched on the extruded polymer sheet (mostly made of polypropylene or high-density polyethylene) and then subjected to directional stretching under heating conditions. Unidirectional stretching grids are only made by stretching along the length direction of the sheet, while biaxial stretching grids are made by continuing to stretch the unidirectional stretching grid in the direction perpendicular to its length. Biaxially stretched plastic geogrid is made of polypropylene (PP) or polyethylene (PE) as raw materials, extruded through plasticization, punching, heating, longitudinal stretching, and transverse stretching.

Application of plastic geogrid:

Geogrid is a high-strength geosynthetic material. Widely used in fields such as embankments, tunnels, docks, highways, railways, and construction.

Its main uses are as follows:

1. Strengthening the roadbed can effectively distribute diffusion loads, improve the stability and bearing capacity of the roadbed, and extend its service life;

2. Can withstand larger alternating loads;

3. Prevent roadbed deformation and cracking caused by the loss of roadbed materials;

4. Improve the self bearing capacity of the backfill behind the retaining wall, reduce the soil pressure on the retaining wall, save costs, extend the service life, and reduce maintenance costs;

5. Combining the construction method of spray anchor concrete for slope maintenance can not only save 30% -50% of investment, but also shorten the construction period by more than twice;

6. Adding geogrids to the roadbed and surface layer of highways can reduce deflection, reduce ruts, delay the occurrence of cracks by 3-9 times, and reduce the thickness of structural layers by up to 36%;

7. Suitable for various soils, without the need for remote sampling, saving labor and time;

8. The construction is simple and fast, which can greatly reduce construction costs.

Post time: Apr-17-2024