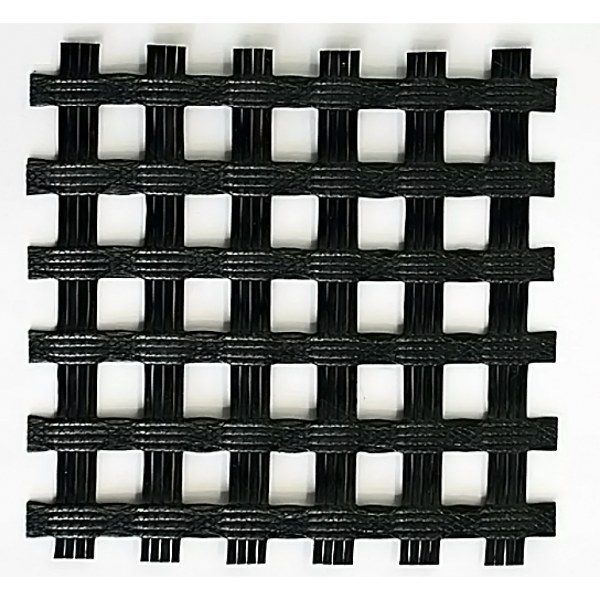

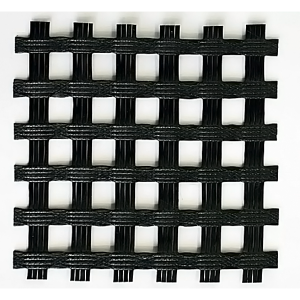

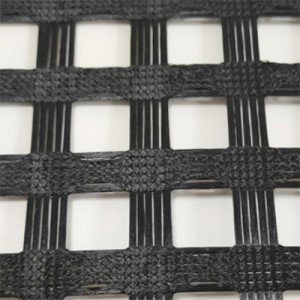

Plastic Grids Biaxial Geogrid For Road Reinforcement

Overview

Quick Details

| Type | Geogrids |

| Warranty | 3 years |

| After-sale Service | Online technical support, Free spare parts, Other |

| Project Solution Capability | total solution for projects, Others |

| Application | Road Construction and Soft Soil Reinforcement, Road Construction |

| Design Style | Modern |

| Place of Origin | Shandong, China |

| Model Number | Geogrid |

| Product name | HDPE Biaxial Geogrid |

| Raw Material | Plastic |

| Color | Customer`s Request |

| Feature | High Tensile Strength |

| Tensile strength | 25Kn/m--300Kn/m |

| LENGTH | 50m/100m/customer Requirement |

| Width | 1-6m |

| Mesh Size (mm) | 12.7*12.7mm. 25.4*25.4mm |

| Certificate | CE /ISO9001 |

Supply Ability : 600000 Square Meter/Square Meters per Month

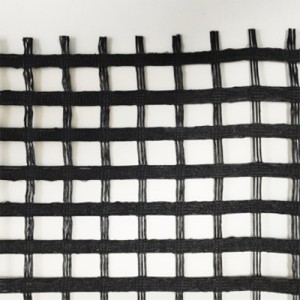

Plastic PP Geogrid

PP Biaxial Geogrid is manufactured from Polypropylene, from the process of extruding, longitudinal stretching and transverse stretching.

PP Uniaxial Geogrid is an integrally formed structure, which especially designed for soil stabilization and reinforcement

applications.

Specification

| Performance/Specification | PET 40-25 | PET 50-35 | PET 60-30 | PET 80-30 | PET100-30 | PET 120-30 | |

| Elongation (%) | 3% | ||||||

| Tensile Strength | warp | 25 | 50 | 30 | 30 | 30 | 30 |

| (KN/m) | waft | 40 | 35 | 60 | 80 | 100 | 120 |

| Performance/Specification | PET 150-30 | PET 180-30 | PET 200-30 | PET 300-30 | PET 400-30 | PET 500-30 | |

| Elongation (%) | 3% | ||||||

| Tensile Strength | warp | 30 | 30 | 30 | 30 | 30 | 30 |

| (KN/m) | waft | 150 | 180 | 200 | 300 | 400 | 500 |

| Mes size(mm) | 12.7X12.7, 25.4X25.4, 40X40 | ||||||

| Roll Width(m) | 1-6 | ||||||

| Roll Length(m) | 50-200 | ||||||

Product Detail

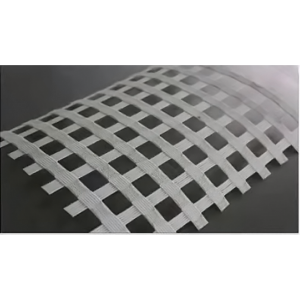

Plastic geogrid is a square or rectangular polymer mesh formed by stretching. It is punched on the extruded polymer plate, and then directionally stretched under heating conditions. plastic geogrid

Stock steel plastic geogrid picture

The material selection of plastic geogrid directly affects the service performance of geogrid products. Therefore, the material is required to have good impact toughness, good environmental resistance and stable performance under long-term use.

1. HDPE is used as the main raw material and rubber is added as the toughening modifier to improve the environmental stress cracking resistance of HDPE. The products produced with this formula have high low temperature resistance and can be used in vast areas. Northwest and Northeast China are particularly suitable.

2. Take PP as the main raw material and add antioxidants to improve the heat aging resistance of PP. the geogrid products produced with this formula can be used at - 23 ~ 70 ℃.

Note: if 2% carbon black is added to HDPE or PP, it can inhibit light aging and prolong the service life of geogrid products.

Product application

The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Geogrids can be used with any kind of mechanical fill material.