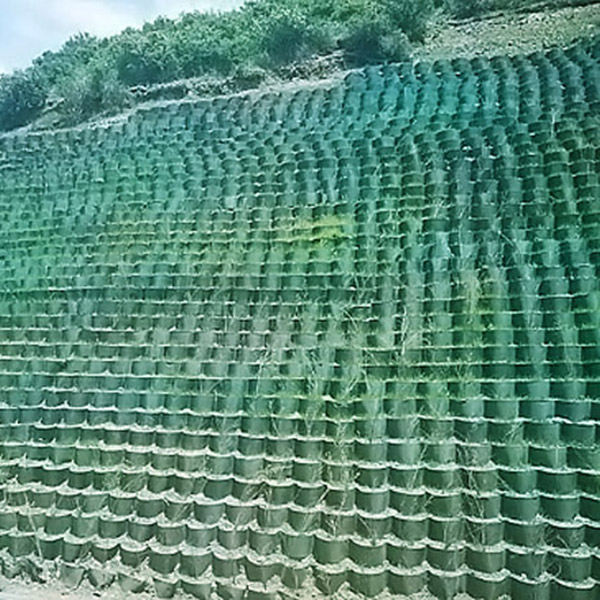

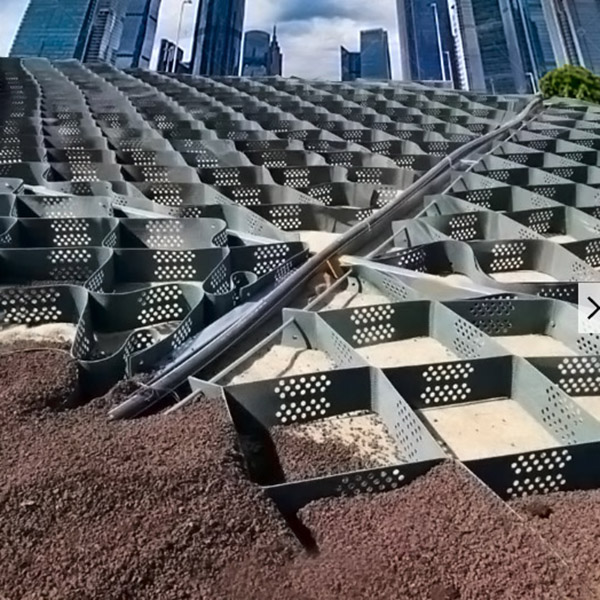

Reinforced Smooth HDPE Geocell for Reinforcement of The Riverbed

Type:Geocells

Warranty:More than 5 years

After-sale Service:Free spare parts, Online technical support, Return and Replacement

Project Solution Capability:3D model design, graphic design, total solution for projects

Application:Road construction and slope protection

Design Style:Contemporary

Place of Origin:Shandong, China

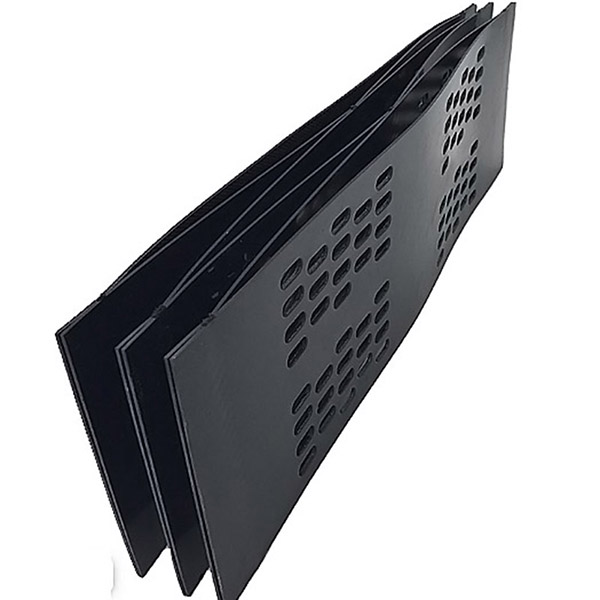

Product Name:Geocell

Material:HDPE

Color:Black,green or as customer

Place of origin:Shanghai,China

Wall thickness:1.0mm 1.3mm 1.5mm 1.7mm

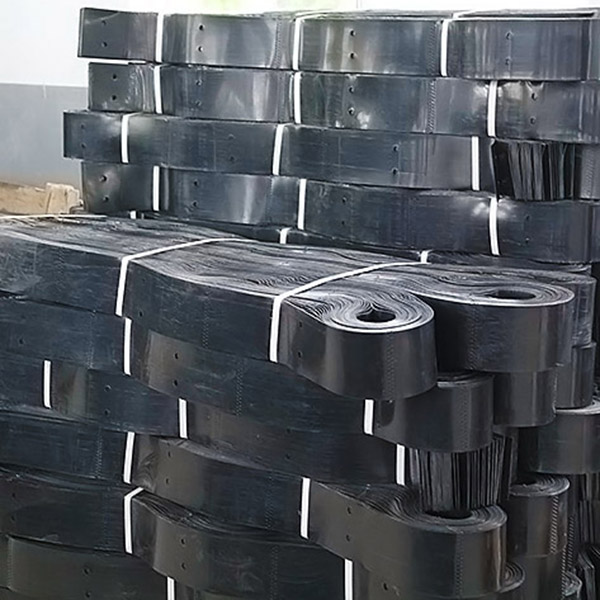

Size/roll:4m/5m/10m*6m one roll

Welding distance:50mm-800mm

Service:OEM and ODM,24 hours online reply

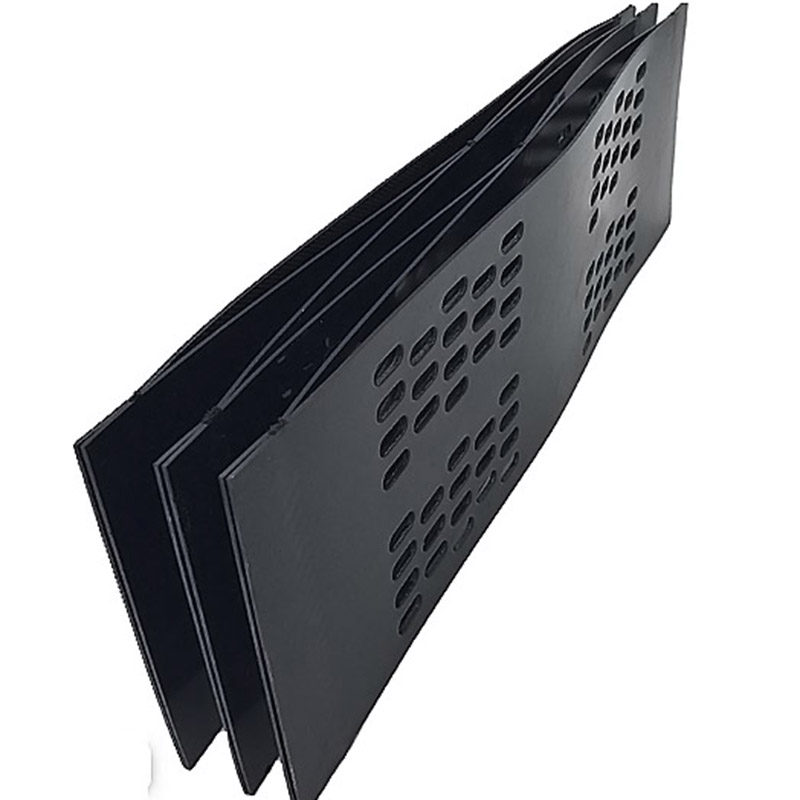

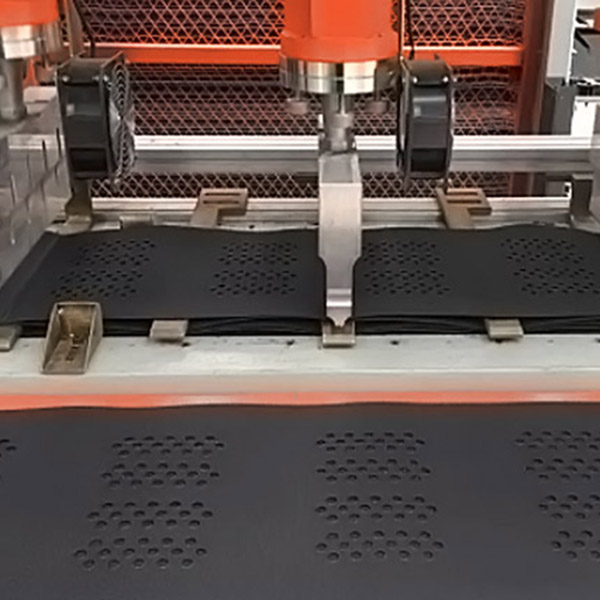

Surface:Smooth Texture Perforation or no

MOQ:20 square Meters

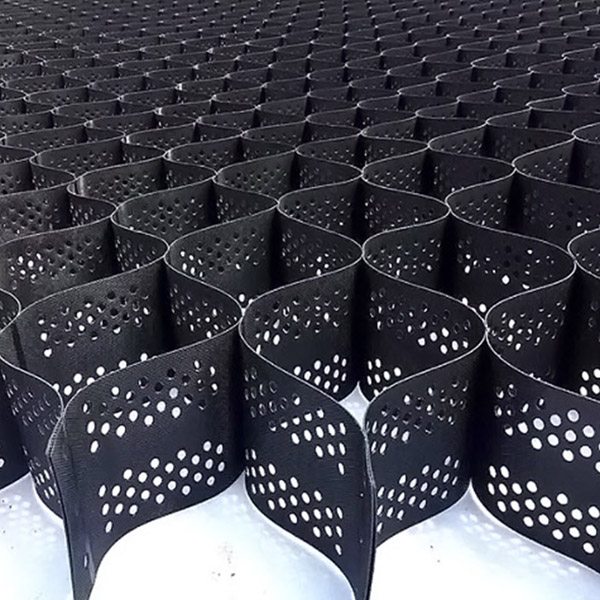

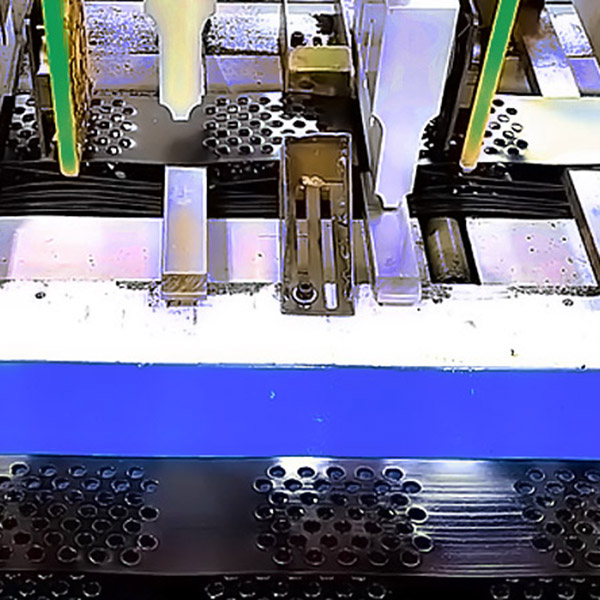

Geocell is a new type of high strength geosynthetic material which is popular at home and abroad. It is a three-dimensional meshcell structure formed by high strength welding of reinforced HDPE sheet material.Due to engineering needs, some need to be drilled in the diaphragm.During construction, it can be stretched into a network and filled with loose materials such as soil, gravel,concrete, etc., to form a structure with strong lateral restrictions and large stiffness.

1.It’s extractile,flexible to fold and convenient for transportation.

2.It can be filled with soil, gravel,earth,macadam and so on when being stretched into network.

3.It has light material, wear resistance, acid and alkali resistance, anti aging.

4.It is anti-skid and anti-deformation and also has a higher lateral limit, which can reduce the thickness of roadbed.

|

Materials Properties |

Test method ASTM |

UNIT |

|

|

Cell Height |

|

mm |

75 100 150 200 |

|

Polymer Density |

D1505 |

g/cm3 |

0.935-0.965 |

|

Environmental Stress Crack Resistance |

D5397 |

Hours |

>400 |

|

Environmental Stress Crack Resistance |

D1693 |

Hours |

6000 |

|

Carbon Black Content |

D1603 |

% |

1.5%-2.0% |

|

Nominal Sheet Thickness Before Texturing |

D5199 |

mm |

1.27-5%,+10% |

|

Nominal Sheet Thickness After Texturing |

D5199 |

mm |

1.52-5%,+10% |

|

Strip Puncture Resistance |

D4833 |

N |

450 |

|

Seam Peel Strength |

EN ISO 13426-18 |

N |

1065 1420 2130 2840 |

|

Seam Efficiency |

GRI-GS13 |

% |

100 |

|

Nominal ExpandedCell Size (width *length) |

|

mm |

475*508, 500*500 etc |

|

Nominal Expanded Panel Size (width length) |

|

mm |

2.56*8, 4.5*5.0, 6.5*4.5, 6.1 *2.44 |

|

Product Type |

Smooth and Not Perforated |

Smooth and Perforated |

Textured and Not Perforated |

Textured and Perforated |

|

Height (mm) |

50≤H≤250 |

50≤H≤250 |

50≤H≤250 |

50≤H≤250 |

|

Welding Distance(mm) |

330≤A≤1000 |

330≤A≤1000 |

330≤A≤1000 |

330≤A≤1000 |

|

Thickness (mm) |

1.0- 1.2 |

1.0- 1.2 |

1.3- 1.7 |

1.3- 1.7 |

|

Seam Peel Strength of Welding Point (N/cm) |

≥100 |

≥100 |

≥100 |

≥100 |

|

Tensile Strength of Connection of Cells (N/cm) |

≥120 |

≥120 |

≥120 |

≥120 |

|

Tensile Strength at Yield of Each Sheet (N/cm) |

≥200 |

≥200 |

≥200 |

≥200 |

Q:Service:

A:OEM/ODM orders are warmly welcome All of our products have proceeded testing before shipment and we guaranteed the good quality.

Q: Why should you buy from us not from other suppliers?

A:good quality and service, timely delivery.

Q: Quality Control:

A:We have established a national-standard laboratory for in-house quality control and built a strict quality control system in all aspects from raw materials testing and production processes to final product quality testing.

Q : Could you send the sample before order confirmation?

A : Yes, we’d love to send a free sample to you for an evaluation if you need.

Q: What about lead time?

A: the quantity is small receive deposit can arrange delivery immediately, the quantity is large 3-5 days, can also arrange delivery time according to customer requirements