Well-designed Woven Polypropylene Geotextile Fabric - Airport Runway Reinforcement Fiberglass Geogrid – Taishan

Well-designed Woven Polypropylene Geotextile Fabric - Airport Runway Reinforcement Fiberglass Geogrid – Taishan Detail:

Overview

| Type | Geogrids |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Project Solution Capability | Others |

| Application | ourdoor, Railways,highways,bridge,approach,wharf |

| Design Style | Industrial |

| Place of Origin | Shandong, China |

| Model Number | GSZ |

| Product name | geogrid |

| Color | Black |

| Raw Material | steel and PE |

| Certificate | ISO |

| Width | 1-6m |

| Length | 50-100m |

| Tensile strength | 30-200kN/m |

| Material | Fiberglass |

| MOQ | 5000sqm |

Supply Ability: 600000 Square Meter/Square Meters per Month

Product description

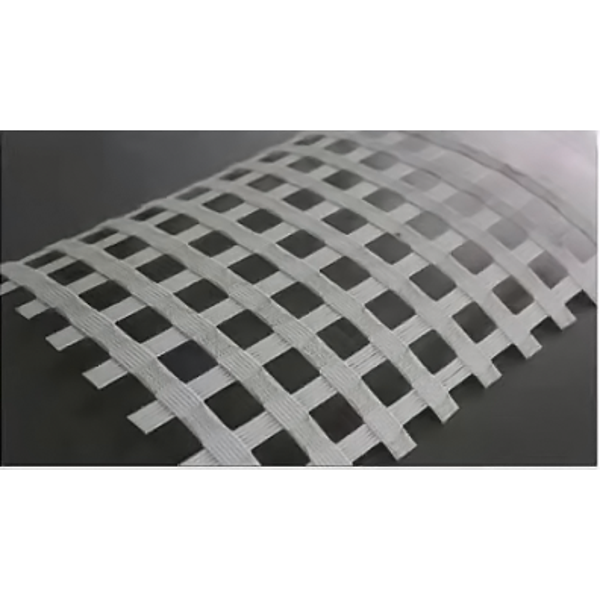

Fiber Glass Geogrid For Road Construction

Fiberglass geogrid is knitted by glass fiber filaments and coated with bitumen to provide a good bond with the asphalt layers, can strengthen the asphalt layer, extend the service life of pavement layers and decrease the occurrence rate of reflective cracking under cyclic traffic load.

High vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.

The products after surface covering own the favorable property of alkali resistance and aging resistance.

Product specification

| Specification | 30-30 | 50-50 | 80-80 | 100-100 | 120-120 | 150-150 | 200-200 | |

| Ultimate Strength

(KN/M) |

MD | 30 | 50 | 80 | 100 | 120 | 150 | 200 |

| CD | 30 | 50 | 80 | 100 | 120 | 150 | 200 | |

| Elongation(%) |

<=4 |

|||||||

| Grid Size, mm |

12.5*12.5,25.4*25.4,40*40 |

|||||||

| Roll Width |

1-6m |

|||||||

| Roll Length |

50-200m |

|||||||

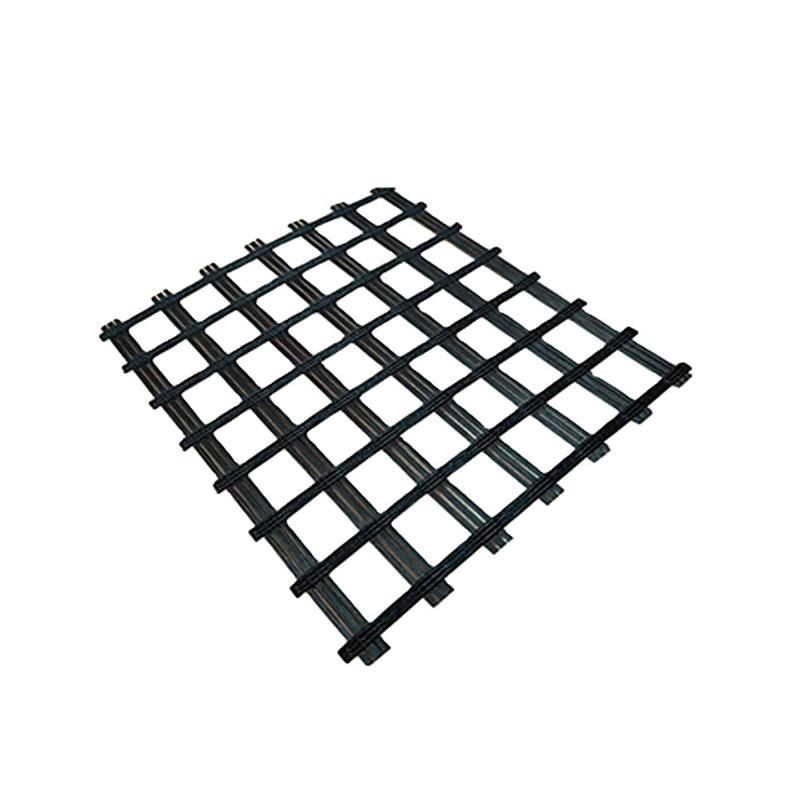

Product features

★ High tensile strength and low elongation. Glass fiber geogrid takes glass fiber as raw material, has high deformation resistance, and the fracture elongation is less than 3%.

★ No long-term creep. As a reinforcing material, it has the ability to resist deformation under long-term load, that is, creep resistance is very important. Glass fiber will not creep, which ensures that the product can maintain its performance for a long time.

★ The melting temperature of thermal stability glass fiber is above 1000 ℃, which ensures the thermal stability of glass fiber geogrid in paving operation.

★ Compatibility with asphalt: the coating material of glass fiber geogrid in the post-treatment process is designed for asphalt mixture, and each fiber is fully coated, which is very similar to asphalt High compatibility, so as to ensure that the glass fiber geogrid will not be isolated from the asphalt mixture in the asphalt layer, but firmly bonded together.

★ Physicochemical stability: after coating with special post-treatment agent, glass fiber geogrid can resist all kinds of physical wear and chemical erosion, biological erosion and climate change, so as to ensure that its performance is not affected.

★ Aggregate interlocking and limitation because the glass fiber geogrid is a network structure, the aggregate in the asphalt concrete can penetrate it, thus forming a mechanical interlocking. This restriction hinders the movement of aggregate, so that asphalt mixture can achieve better compaction state, higher bearing capacity, better load transfer performance and less deformation under load.

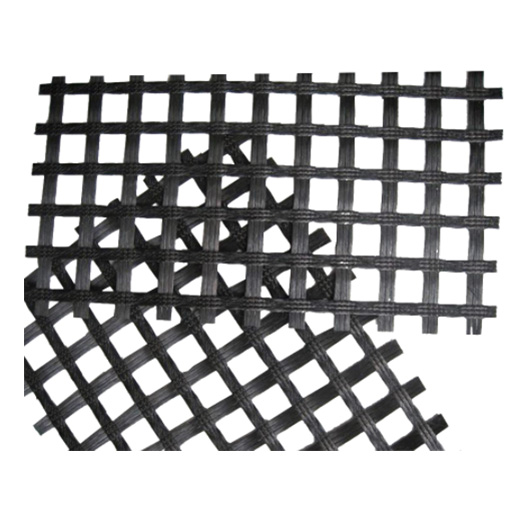

Product application

Road Widening , Airport Runway reinforcement , Road Pavement reinforcement , Road Maintenance and Repair

Product detail pictures:

Related Product Guide:

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for Well-designed Woven Polypropylene Geotextile Fabric - Airport Runway Reinforcement Fiberglass Geogrid – Taishan , The product will supply to all over the world, such as: Boston, Tanzania, Moscow, Nowadays our merchandise sell all over the domestic and abroad thanks for the regular and new customers support. We supply high quality product and competitive price, welcome the regular and new customers cooperate with us!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.